DT-type dense-phase pneumatic conveying system according to the domestic advanced technology and experience, combined with scientific experiments, after several years of practice, was identified as an economical and reliable pneumatic conveying system. The system to transport high ash ratio, low gas consumption, low delivery speed, effectively reduce the pipeline wear. The system consists of compressed air gas source, DT type transmitter, control cabinet, conveying pipe, ash library five parts.

First, the compressed air Gas source:

It is composed of air compressor, oil separator, dryer, gas tank and pipeline, mainly for the transmitter and air control components to provide high-quality compressed air.

Second, the transmitter:

Accept the dust collector set ash bucket fly ash, after fluidization through the conveyor tube sent to the ash library.

Third, the control cabinet:

The computer centralized control of various mechanical components action, and with manual operation mechanism.

Fourth, the pipeline:

Experiments, transport distance of up to 1300 meters, pipeline life of up to 20,000 hours or more.

Five, ash library:

From the ash library body, bag filter, vacuum release valve, level meter, ash removal equipment and other components.

⊙ DT-type dense-phase pneumatic conveying system layout

⊙ process description

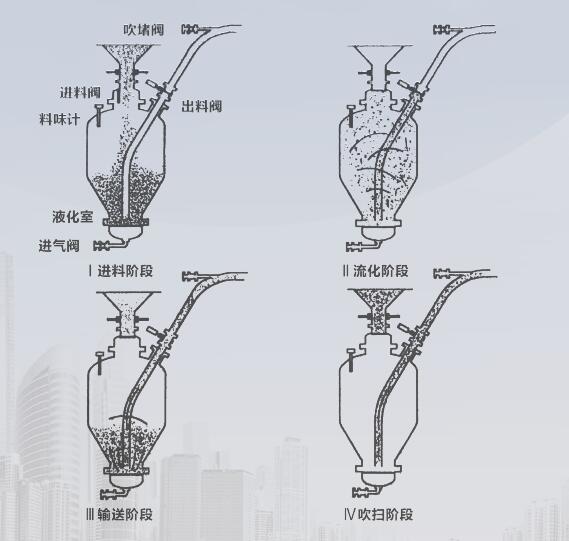

DT-type positive pressure transmitter process is divided into four stages:

1, the feed stage

The feed valve is opened and the material is free to fall into the transmitter. When the material in the transmitter reaches the level meter, the material level is discharged and the feed valve is automatically closed to complete the feeding process.

2, fluidized pressure stage

The intake valve is automatically opened, compressed air enters the bottom of the transmitter, spreads through the fluidized bed, the material is fully fluidized by the colleague, and the air pressure inside the transmitter rises.

3, the delivery phase

When the pressure inside the transmitter reaches a certain value, the pressure sensor sends out the signal, the discharge valve automatically opens, the fluidized bed material fluidization strengthens, the transportation begins, the material in the transmitter gradually reduces, in this process the material on the bed In the edge of the flow lace delivery.

4, the purge stage

When the material within the transmitter is finished, the pressure drops to the pipe resistance, the indicator light signals, the ventilation continues for a certain time, the compressed air purge the pipe, and then the intake valve closes, the interval time, closes the discharge valve, opens the feed valve, Complete a delivery cycle.

⊙ positive pressure transmitter transmitter working principle diagram